Kagure no Wardrobe #01 held its 4th planning meeting after a one-month hiatus.

[Until last time]

1st 2016/7 #01-1 REPORT ~ Consideration of production items ~

2nd 2016/8 #01-2 REPORT ~ Design review ~

3rd 2016/9 #01-3 REPORT ~Toilet Check/Fabric Examination~

Starting from the concept, we spent a lot of time discussing things such as item selection and Kagura's original clothes in the early stages, solidifying the image. In the last 3rd time, I was able to see and touch the concrete shape by creating the toile. Although the fabric was a tentative sheeting material, discussions on the design and pattern progressed quickly, and we narrowed down the approximate design pattern and fabric candidates.

This time, the 4th time, Mr. Machida of enrica made a sample with the fabric that was influential among the candidates. Based on this 1st sample, the specifications are examined and revised, and the fabric is selected from the newly reselected fabric candidates.

The moment the cover was removed, the samples were taken out and hung, the meeting began with everyone exclaiming, "As expected!" Although it is the 1st sample, the design, pattern, and sewing finish make the silhouette very beautiful. There is a presence of simple but beautiful clothes. Thank you enrica Machida for your wonderful work as always! !

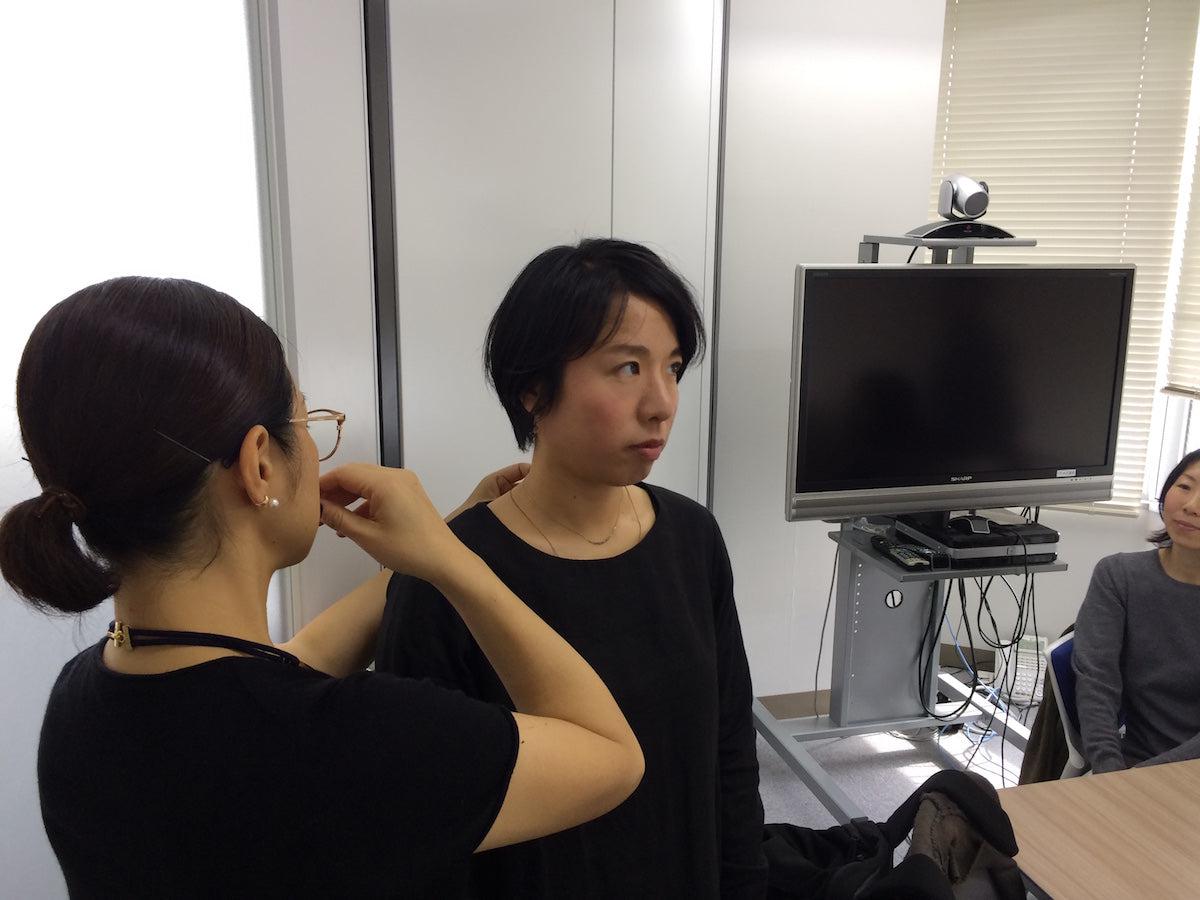

First of all, Mr. Okuda tried it on as usual. When you wear it, you can see the shape more, and the fabric feels beautiful. The meeting has just started, but all the members are heating up, saying, "Good! Very good!"

[Until last time]

1st 2016/7 #01-1 REPORT ~ Consideration of production items ~

2nd 2016/8 #01-2 REPORT ~ Design review ~

3rd 2016/9 #01-3 REPORT ~Toilet Check/Fabric Examination~

Starting from the concept, we spent a lot of time discussing things such as item selection and Kagura's original clothes in the early stages, solidifying the image. In the last 3rd time, I was able to see and touch the concrete shape by creating the toile. Although the fabric was a tentative sheeting material, discussions on the design and pattern progressed quickly, and we narrowed down the approximate design pattern and fabric candidates.

This time, the 4th time, Mr. Machida of enrica made a sample with the fabric that was influential among the candidates. Based on this 1st sample, the specifications are examined and revised, and the fabric is selected from the newly reselected fabric candidates.

The moment the cover was removed, the samples were taken out and hung, the meeting began with everyone exclaiming, "As expected!" Although it is the 1st sample, the design, pattern, and sewing finish make the silhouette very beautiful. There is a presence of simple but beautiful clothes. Thank you enrica Machida for your wonderful work as always! !

First of all, Mr. Okuda tried it on as usual. When you wear it, you can see the shape more, and the fabric feels beautiful. The meeting has just started, but all the members are heating up, saying, "Good! Very good!"

100% linen, black fabric that is not heavy in color. While it has a linen-like crisp feel, it is soft to the touch and feels like it is made of high-quality linen thread. It was a fabric with a mature and elegant atmosphere.

A belt string made of the same fabric that is attached to the dress as a set. This thickness matched with an exquisite balance. By simply wrapping and tying it like this, you can adjust the silhouette and completely change the impression. (You can wear it without wearing it, so you can choose it as you like.)

A belt string made of the same fabric that is attached to the dress as a set. This thickness matched with an exquisite balance. By simply wrapping and tying it like this, you can adjust the silhouette and completely change the impression. (You can wear it without wearing it, so you can choose it as you like.)

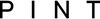

Take turns trying on clothes. Even the same clothes show various expressions depending on the clothes to match and the person who wears it. each one is nice. Since it is not a front opening type, smoothness when putting on and taking off is also an important point. Focusing on the fabric and pattern while checking the comfort.

Carefully check the silhouette, the length of the belt strap, the length of the sleeves and body, and the neckline. One size is available, so we will search for the best shape and size that can be worn in a wide range of ways. It was a very difficult point, but since there were a lot of participating staff members, we all had a lot of discussions while thinking about the customers of each store while trying on the clothes. While making full use of the advantages of this project, we will try to match it while receiving advice from Mr. Machida on the structure and balance of the clothes so that it does not become a mere greatest common denominator.

Even just 1cm around the neck can change the impression surprisingly.

The sample color this time is black linen fabric, and the long sleeves are long and the fabric area is wide. However, depending on your body shape, you may be concerned about the amount of space in the collar... It is literally a fine line.

This review was repeated for each location to determine design and pattern modifications. Of course, it's not just a matter of doing each one in order, it's a very important and difficult process because it's an adjustment that always considers the overall balance.

The sample color this time is black linen fabric, and the long sleeves are long and the fabric area is wide. However, depending on your body shape, you may be concerned about the amount of space in the collar... It is literally a fine line.

This review was repeated for each location to determine design and pattern modifications. Of course, it's not just a matter of doing each one in order, it's a very important and difficult process because it's an adjustment that always considers the overall balance.

Consider the fabric as well. The atmosphere of the 1st sample this time, which Mr. Machida chose based on the contents of the previous meeting, was very good, and the material was linen as originally planned. There are various types of linen fabrics, such as thread count (thickness), color patterns, and processing. We will select linen fabrics from the new fabric candidates prepared by Mr. Machida.

This sample is the 1st, but we plan to make the next 2nd the final sample. Along with the modifications to the previous specifications, we will check everything together by changing the type and color of the fabric. I spent most of the time in the second half of this meeting choosing fabrics and colors.

What should be checked with priority in the 2nd sample? Are you going to try changing the fabric, or are you going to stick with the 1st sample and check other colors? After much deliberation, I decided to use the same fabric as the 1st sample. After going back and forth and accumulating opinions from various angles, in the end, when everyone's wishes were taken all at once, they were unanimous in this fabric.

As for the color development that I am interested in, at the moment the proposal of "3 colors + 1 special color" is the most promising, but we will continue to consider it at the next meeting, so I will leave it to the next time. By the way, the 2nd sample will be made in one of the three colors. We look forward to seeing you in the next report.

What should be checked with priority in the 2nd sample? Are you going to try changing the fabric, or are you going to stick with the 1st sample and check other colors? After much deliberation, I decided to use the same fabric as the 1st sample. After going back and forth and accumulating opinions from various angles, in the end, when everyone's wishes were taken all at once, they were unanimous in this fabric.

As for the color development that I am interested in, at the moment the proposal of "3 colors + 1 special color" is the most promising, but we will continue to consider it at the next meeting, so I will leave it to the next time. By the way, the 2nd sample will be made in one of the three colors. We look forward to seeing you in the next report.

This time, too, the two hours went by in a flash, and it was a very intense meeting.

Based on the above content, enrica Machida will prepare a second sample (different color of the same fabric) that reflects the detailed specifications and pattern changes. Since we had to arrange the fabric and secure the production schedule, we decided to do the next (fourth) earlier just in case, and decided on 11/2.

Finished 4th out of 5. From planning to production, in the planning stage today, the 4th to 8th stations will run up at once, and we will finally reach the final stage. Next time, the shape and fabric color will be finalized, the planning stage will be over, and after that we will enter the production stage.

Kagure's original dress, planned and produced over a period of more than half a year. We are distributing reports on product planning for clothes making from scratch. Through this project report, please take a look at how one piece of clothing is made.

Here is the upcoming schedule ↓

//////////////////////////////////////////////////// //////

[Kagure no Wardrobe #01 Schedule]

2016/7 #01-1 REPORT ~Examination of production items~ <End>

2016/8 #01-2 REPORT ~Design Review~ <End>

2016/9 #01-3 REPORT ~Toilet Check/Fabric Examination~ <End>

2016/10 #01-4 ~ 1st sample check and fabric consideration ~ <this time>

2016/11 #01-5 ~ 2nd sample check / final decision ~ <next time>

2017/1~2 production

Released March 2017

*Next time onwards is planned. Subject to change.

//////////////////////////////////////////////////// //////

Based on the above content, enrica Machida will prepare a second sample (different color of the same fabric) that reflects the detailed specifications and pattern changes. Since we had to arrange the fabric and secure the production schedule, we decided to do the next (fourth) earlier just in case, and decided on 11/2.

Finished 4th out of 5. From planning to production, in the planning stage today, the 4th to 8th stations will run up at once, and we will finally reach the final stage. Next time, the shape and fabric color will be finalized, the planning stage will be over, and after that we will enter the production stage.

Kagure's original dress, planned and produced over a period of more than half a year. We are distributing reports on product planning for clothes making from scratch. Through this project report, please take a look at how one piece of clothing is made.

Here is the upcoming schedule ↓

//////////////////////////////////////////////////// //////

[Kagure no Wardrobe #01 Schedule]

2016/7 #01-1 REPORT ~Examination of production items~ <End>

2016/8 #01-2 REPORT ~Design Review~ <End>

2016/9 #01-3 REPORT ~Toilet Check/Fabric Examination~ <End>

2016/10 #01-4 ~ 1st sample check and fabric consideration ~ <this time>

2016/11 #01-5 ~ 2nd sample check / final decision ~ <next time>

2017/1~2 production

Released March 2017

*Next time onwards is planned. Subject to change.

//////////////////////////////////////////////////// //////